Company News

Roller conveyor: the new driving force of logistics transportation, intelligent upgrading to lead the industry change

In today's fast-developing logistics industry, roller conveyor, as a representative of intelligent conveying equipment, is becoming an indispensable and important part of the logistics conveying system with its high efficiency and flexibility. Through a series of well-designed rollers, roller conveyor builds up an intelligent and efficient conveying platform in the frame, which is widely used in the conveying of various kinds of bags, pallets and other pieces of goods, and greatly improves the efficiency and accuracy of logistics operations.

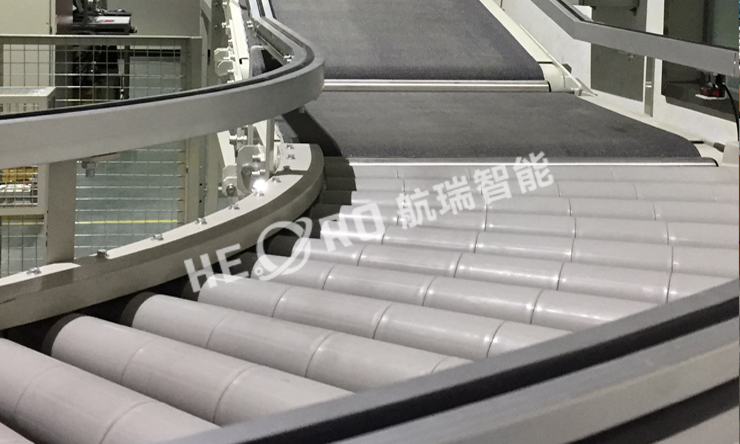

Roller conveyor meets the diversified needs of different logistics scenarios with its diversified product classification. According to the arrangement form, roller conveyor can be divided into straight line type, turning type, slope type, bifurcation type, multi-layer type, spiral type and telescopic type. Straight roller conveyor is suitable for long-distance and continuous material conveying; turning type can realize flexible turning of goods in limited space; slope roller conveyor can easily cope with different heights of goods conveying needs. Bifurcated, multi-layer, spiral and telescopic roller conveyors further expand the scope of roller conveyor applications, so that it can better adapt to the complex and changing logistics environment.

In addition, according to the weight of the goods to be transported, roller conveyors can also be divided into two categories of light and heavy. Light roller conveyor is mainly used for conveying boxes, bags and other lightweight goods, with a simple structure, easy maintenance; while the heavy roller conveyor is designed for pallets and other heavy loads, with a strong carrying capacity, stable operation. This categorization makes the roller conveyor able to accurately match different weights of goods, ensuring the safety and high efficiency of the conveying process.

Driven by the wave of intelligence, roller conveyor is constantly upgrading and developing in the direction of more intelligence and high efficiency. Modern roller conveyor is not only a simple conveying tool, but also integrates advanced sensing technology, automation control technology and data analysis technology to realize real-time monitoring and accurate control of the conveying process. The application of these technologies not only improves the operational efficiency of the roller conveyor, but also reduces the failure rate and extends the service life of the equipment.